| Careers | Contact Us | Home |

|

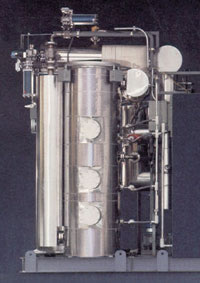

ENVIRONMENTAL SYSTEMS Flue Gas Conditioning Systems Sulfur Trioxide FGC Systems Hundreds of these systems are in operation worldwide to reduce flyash resistivity when burning low to medium sulfur coal. Elemental sulfur is burned in air to form sulfur dioxide gas which is then catalytically converted to sulfur trioxide gas and injected into the flue gas stream ahead of the precipitator. Typical injection rates are 5 to 10 ppm (about 40 to 80 lb/hr sulfur feed for a 600 MW boiler). Sulfur is available in either molten or solid form. Molten sulfur (readily available in most industrialized countries) is preferred because of lower cost, less handling and higher system reliability. The energy consumption of our patented sulfur burning system is a little less than 10% of other systems and requires 50% less process air. As a result, both installation and operating costs are lower. Advantages of Chemithon SO3 FGC Systems:

Retrofits of Flue Gas Conditioning Systems Modern FGC systems are far more reliable, more efficient and offer lower operating costs than older systems. Retrofitting to modern designs can dramatically improve precipitator performance and reduce the potential for expensive plant derates (often recovering the cost of retrofitting in a matter of weeks or months). The most common retrofits are:

For More Information: Hal Busick

|

Ammonia Systems (anhydrous and aqueous)

|

___________________________________________________________________________________________________________________ 2013 Copyright All Rights Reserved Chemithon Corporation..... . . .. ........... ..... ........... . ..... .. .Website: Travis Design Associates ~ Seattle |